How Many Amps Can 18 Gauge Wire Handle 48v?

Have you e'er wondered how many amps exercise you demand for a MIG welder? Few things are more important for welders than making certain that they have the proper amount of amperage.

Also little amperage and you might not be able to spark your welder to life, permit alone accept the rut and power necessary to melt and weld solid metallic.

Too much and yous might scorch the metal, cause the metal to bead, or overload the welder and potentially even crusade information technology to explode.

How many amps practise yous really need for a MIG welder? In boilerplate you need 140 amps for 115 volts welders in lodge to weld up to ¼" thick steel and effectually 200 amps for 220 volts welders and weld up to ½" thick material.

How Many Amps Do I really Need for a MIG Welder?

You need to remember that the amperage depends on many factors similar the type and thickness of the material . how many amps for a welder?

The answer to that question will change depending on what type of welder you're using.

MIG welding is the selection of choice for many welders – especially beginners – which sparks another question – "how many amps to run a welder"

Are you going to exist welding mild steel ? Or do you anticipate working with stainless steel, aluminum, or an exotic metal or alloy?

What is the thickest thickness of the material that yous wait to take to join? Knowing the answers to these questions will help you determine how much machine you need.

It'south always amend to have a piddling bit more than than you'll need because even the kind of bring together that y'all're welding can influence the amperage settings you'll demand to go the job done right.

Related reading: I have recently written an article in which I describe "5 Types of Welding Joints and Their Apply – Consummate Guide" in more item, read this commodity here.

If you lot're welding mild steel using stick welding techniques, the blazon of electrode that you're using will influence the suggested amperage range.

E6013 is an all-purpose electrode that volition weld 2mm mild steel with an amperage setting betwixt 35 and 60.

At the same time, an E6010 or E6011 electrode will require a range of twoscore to 85 amps.

To TIG weld mild steel that is 2mm thick, you will need 60 amps for a closed root butt joint, 75 amps for a fillet articulation, and only 55 amps for a lap joint or an outside corner.

For MIG welding balmy steel, a good rule of thumb is to adjust the welder amperage level using one amp for every thousandth of an inch of thickness.

That would mean that 75 to 80 amps would be a expert setting to start out on for balmy steel that is 2mm in thickness.

The welder amperage range that is appropriate will alter depending on the type of material you are welding and the thickness of that material.

So, y'all will need to accept the range of materials that you lot desire to be able to piece of work on into consideration when you are determining how many amps you'll need.

Let's accept a closer await at how amperage for welders work, the specifics of amperage and MIG welding, and how you can keep your unit at the right setting.

Type of Material

First and foremost, you're going to desire to consider what blazon of material y'all are welding. Different materials have different degrees of strength, and different metals have different melting points.

Those are a lot of points of differentiation, which means that you can't and shouldn't employ the same corporeality of amperage for unlike materials.

Amongst the most common metals used in welding are aluminum, stainless steel, and depression carbon steel.

For welding these also every bit other metals, you'll want to make utilise of a melting point calculator to decide how hot you lot need your welder to exist to melt and weld it effectively.

At that place is as well the fact that not all varieties of a given metal are created every bit, or have the same welding properties.

For case, in that location are three basic types of stainless steel: austenitic, ferritic, and martensitic. You'll desire to differentiate between them when determining how much heat and, thus, the welder amperage is needed to effectively cook and weld with each.

Intergranular corrosion occurs when stainless steels are exposed to loftier temperatures – like, say, in welding – which can in turn make them more difficult to weld.

While austenitic and ferritic stainless steels are generally very weldable, martensitic stainless steels are harder and are more liable to fissure, thus, making them harder to weld with.

Every bit a issue, you may need more amperage to bargain with them.

What about low carbon steel?

Well, if yous're looking for an easy-to-weld metal with a MIG welder, you're in luck. Depression carbon steel is highly weldable, requiring less effort, thus, amperage than other metals.

One reason for this is that its low carbon content makes it less ductile, which in turn makes it less brittle, thus, avoiding the cracking bug common in martensite stainless steel.

wire size

Select your wire size, co-ordinate to amperage. We recommend not to change wire, therefore select your most commonly used thicknesses.

| Wire Size | Amps |

|---|---|

| .023 inch | 30-130 amps |

| .030 inch | xl-145 amps |

| .035 inch | l-180 amps |

| .045 inch | 75-250 amps |

Set Your wire feed speed.

The amperage depends on wire speed as well as the amount of weld penetration.

Besides loftier speed can pb to fire-through. We recommend to read your manual or the weld specification sheet.

Equally a general dominion use the multipliers in the following table nautical chart to determine your wire speed.

i.eastward, for .030-inch wire, multiply past 2 inches per amp to find the wire feed speed in inches per minute (ipm).

| Wire Size | Multiply past | using 1/8 inch (125 Amps) |

|---|---|---|

| .023 inch | three.5 inches per amp | iii.5 x 125 = 437.five ipm |

| .030 inch | ii inches per amp | two x 125 = 250 ipm |

| .035 inch | 1.vi inches per amp | one.half dozen x 125 = 200 ipm |

| .045 inch | 1 inch per amp | 1 ten 125 = 125 ipm |

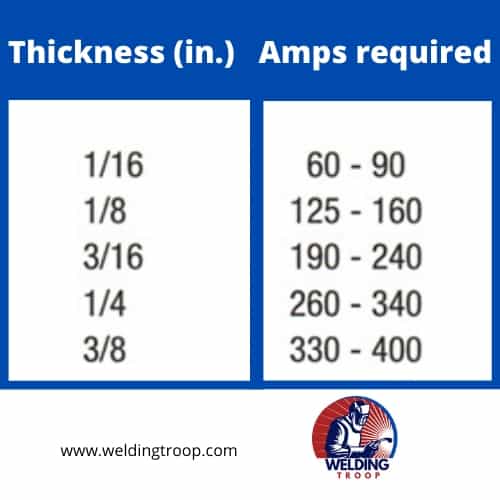

Material Thickness

Even if yous are a beginner MIG welder, it shouldn't come equally too much of a surprise that thickness plays a huge part in determining how much oestrus, power, and, thus, amperage yous need to weld something.

That said, while thickness is always meaning, the bodily amperage difference can vary a great deal depending on the type of metal being welded.

In the example of aluminum, for case, a practiced rule of thumb in TIG welding is i amp per 0.001 of thickness.

That said, this dominion begins to break downwardly at more than ¼ inch in thickness.

On the whole, the thicker the piece of aluminum, the less the amperage goes up. The same bones rule holds true for MIG welding as well.

The amperage for stainless and low carbon steel tends to be a bit less intense, requiring only 2/3 of an amp for every 0.001 of thickness, which works out to an average of effectually twoscore amps per 1 mm.

Fifty-fifty thickness is dependent upon other factors; however, including the direction of the heat catamenia.

After all, the reason more amperage is needed at greater thicknesses is that more heat flow is needed to successfully cook and weld the expanse.

If some of that heat menses is prodigal, some of that oestrus is lost, and, thus, you will demand even more than rut than y'all might have needed if the flow had been more concentrated.

| Gauge | Metal Thickness (mm) | Metal Thickness (Inches) | Required Amps |

|---|---|---|---|

| 8 | 4,2 | .164 | 164 |

| 10 | 3,4 | .135 | 135 |

| 12 | 2,7 | .105 | 105 |

| 14 | one,9 | .075 | 75 |

| 16 | 1,5 | .060 | lx |

| 18 | 1,2 | .048 | 48 |

| twenty | 0,9 | .036 | 36 |

| 22 | 0,8 | .030 | 30 |

| 24 | 0,half-dozen | .024 | 24 |

A adept case of this is joints. In these pieces, the oestrus catamenia is dissipated out in the different directions to which the joints extend and adhere to other pieces of metallic.

As a outcome, the heat flow and, thus, amperage necessary to weld these pieces volition be greater than their directly-edged counterparts.

Concluding, but not least, it is worth noting the amount of voltage you'll need to power the welder itself. 110v per every i/4in is a good metric with which to start your welding piece of work.

How You Programme on Using the Welder

The thickness of the material that you're welding is 1 matter, only what are y'all welding it for in the start identify? The bodily welding job y'all're trying to perform can take a big impact on how many amps you need to power the unit of measurement.

If you are doing a job that requires extra power, y'all're naturally going to need extra amperage.

Welding gates, mechanism, and other things typical of subcontract piece of work typically take an amp welder with at least 200v.

Even so, if you are looking to do higher-octane work, or are performing tasks that require a three-phase welder, you lot'll demand something with somewhere between 300 and 600 amps.

Related Commodity: What Gases Do MIG Welders Use >> Welding Shielding Gas | Complete Guide

On the other hand, if you lot are just using your MIG welder for hobbies or lower-level projects, you shouldn't demand that much amperage. A 110v machine that tin can produce 140 amps should exist sufficient.

You'll too want to think about where you're using that welder. Most homes' power sockets can support that 110v range, but above that, you'll likely need to buy an adaptor or generator to brand sure that your power source can handle the amount of amperage necessary for the job.

Related reading: Portable Welding Machine Heir-apparent´s Guide: 5 Things To Look For

How Many Amps Does a Welding Machine Use?

Even if you were talking about a specific welding car, the question of how many amps that it uses would nevertheless require a lengthy answer.

That is because almost any modern welding motorcar will take adjustable amperage settings that allow the user to fine-tune the machine's function to brand it more than powerful when more than ability is required and easier to control when that is what the job calls for.

How many amps does a welding auto use? The answer depends on the machine that you are talking about. But some would argue that it isn't fifty-fifty the correct question to ask.

The number of amps that a welder needs to deliver depends on the kind of welding that is being done, the type of material or materials being welded, the thickness and cleanliness of the materials, and more.

Information technology is like shooting fish in a barrel to find welding machines that evangelize what information technology takes to complete small jobs on lighter materials.

Ofttimes these machines are affordable, easy to set-up, easy to apply, and easy to maintain.

But these machines tend to have express power and typically aren't what you'll desire if you're doing jobs that are bigger, more technically complex, or involve challenging conditions.

Related reading: How Many Types of Welding Machines Are There And Their Uses?

How Much Amperage Should Yous Await for In A Welder?

Welding is one of the nearly useful skills that you can learn. Whether you want to brand welding your primary occupation or just want to be able to brand repairs to equipment around your subcontract or shop, there is a lot that tin exist achieved with bones knowledge and skills.

Welding plays a role in everything from the arts to heavy manufacture. It makes sense that what works for modern sculpture isn't the same as what works for shipbuilding or industrial ironworking.

Ane of the first questions you need to enquire about a welding motorcar is whether yous'll be using it for a specialized job or whether you need it to be good for piece of work as a generalist.

The type of work that you practice will determine whether you want a MIG, TIG, or stick welder as well as how much power you need from the machine.

College amperage will requite y'all more options, but it might come up with tradeoffs similar a higher cost tag and lower portability that will make a high amp car less desirable.

Higher amperage volition give you deeper penetration that makes it possible to weld thicker materials and work faster and cleaner.

Amperage is too a cardinal determiner of the duty cycle, which influences the corporeality of time that you tin can piece of work before letting the machine balance.

If you're shopping for a welding machine, y'all should ask how many amps you need too as how many you're able to run and how many your budget will permit.

By budgeted your purchase this way, you'll be able to find a motorcar that will practice the jobs yous demand it to do without taking on the burden of rewiring your workspace or overspending your budget for no reason.

Questions to Ask Earlier You lot Purchase a Welding Machine

If you lot're simply getting into welding and haven't settled into a preference, y'all volition demand to practise some research.

There are at to the lowest degree three welding techniques that are mutual currently, and many high-cease machines will give you the ability to utilise more than than one technique. Some machines volition even allow y'all to switch betwixt all three.

Stick welding is probably the easiest and most basic technique to learn, but it is merely easy in a limited number of circumstances, and it can exist difficult to get good results on some materials or thicknesses.

MIG and TIG welding are a flake more complicated to learn, but they give welders a wider range of capabilities in terms of what they tin can work on and where they can piece of work.

Whether yous choose stick welding, MIG, or TIG, will help to determine how many amps you will demand from your auto to exist able to exercise the kinds of work that you want to exercise.

In that location are many jobs that you can do with any one of the three techniques, simply the technique yous employ will assist determine the amperage requirements for the task.

I have recently written an commodity in which I depict "the unlike types of welding machines and their uses" in more particular, read this article hither.

How Many Amps Tin can You Run?

Welding machines that are powerful enough to deliver higher amperages are typically 3 phase machines that require access to iii-phase power.

That isn't an selection for virtually homes or hobby shops. Even if a heavy-duty 3-prong or four-prong outlet is available, you lot might withal demand to upgrade your circuit breakers earlier you lot can run a heavy-duty motorcar capable of delivering 300 to 600 amps.

Fortunately, 150 to 200 amps volition exist enough for the vast majority of welding tasks. That means that 115v or 220v outlets will exist all that you'll need to run your machine.

Unless you're shopping for a auto that can run a 100% duty bike on challenging materials , y'all should exist able to become more than than plenty machine without getting into rewiring or major renovations.

How Many Amps Tin You lot Afford?

When it comes to purchasing a welding machine, it pays to spend a little bit more to get more motorcar than yous recall you'll need and make sure that information technology is a quality slice of equipment that volition perform for a long time.

At the aforementioned time, it won't do you any good to spend too much to get the biggest and all-time auto if you lot'll never use one-half of the power or features that come up with it.

Why Higher Amperage Matters

Having covered what factors contribute to the selection, it is worth taking a closer wait at why college amperage matters in the showtime place. While you don't want to do things, higher amperes tend to be easier to piece of work with.

There are several benefits of using higher amperages, not the to the lowest degree of which beingness that more than amperage simply means more than options.

The more heat and power y'all tin generate, the greater your range of welding possibilities, which is always a expert affair.

Then, in that location is the thing of actually penetrating the metal itself. The harder or thicker the metal is, the harder this will be, which volition naturally require more attempt on your role.

That said, this can get wearisome and exhausting all also speedily. As well, the amount of endeavour and force you can personally give to the project is finite.

Calculation extra amperage to the mix can, thus, exist a great way to lessen the difficulty for yourself. After all, if there is more than amperage and, thus, rut involved, the metal in question can exist melted that much more than rapidly, thus, requiring less welding time from yous .

Of course, you'll need to make sure that you practice this in moderation. Adding too much amperage likewise apace tin cause burning and other severe condom bug. That said, practiced properly, more amperage means less toil.

This is especially true when welding thicker materials. As already mentioned, the thicker the metal, the more amperage information technology will take. Kicking that number upward quicker while observing safety protocols can help yous weld thicker and quicker.

Finally, there is the fact that higher amps provide greater consistency. At lower amperages, the work takes longer, which ways there is more time to make mistakes.

College amperes expedite the process. They can also aid you lot weld that much smoother. As a issue, you lot can weld away all those little imperfections, producing piece of work which is smoother, more consistent, and thus of greater quality.

Past taking these factors into consideration, you tin brand sure that you are able to power your MIG welder with enough amperage to get the job done.

Can I Run A Welder On A xxx Amp Breaker?

Tin can I run a welder on a 30 Amp breaker? Yes, In the case of smaller welders with 115v, y'all will be able to run them on a 20 to thirty Amp breaker. For a 220v welder it is non possible to operate on depression amperes and would require 30 amperes minimum but more than 30 amp is recommended.

In the cease it all comes downwardly to your usage and the intensity of the project. If yous plan to use the MIG welder for smaller projects such every bit daily maintenance piece of work effectually the house, and then performance of small welder can work perfectly on a 30 Amp breaker.

However, it is of import to note that a 30 Amp billow volition not trip if y'all hit xxx Amp limit but it will lessen the time catamenia for information technology.

How Thick Can A 180 Amp MIG Weld?

How thick can a 180 Amp MIG weld? A 180 amperes MIG welder is qualify for welding up to 0.035 inch. In some cases, ½ of an inch can be welded. All the same, its penetration level is not as constructive.

Thicker than the mentioned parameters (0.035 inch) would adversely affect the penetration level hence requiring a lot more than effort.

When it comes to MIG welder amps steel thickness it's important to understand that welders utilizing single pass are 1 ampere per 0.001 inches of thickness. This can also be understood as 250 amps per every ane/4th of an inch.

How Thick Can A 70 Amp Welder Weld?

How thick tin a 70 Amp welder weld? seventy Amp welders are perfect for welding upwardly to 1/eight inch thick sheets. This proves a seventy amp to be the best match for intricate work and minor welding projects.

seventy Amp welders are pocket-size and portable welders that are extremely convenient when information technology comes to using information technology for lightweight purposes.

Although 70 Amp welders are non heavy duty, it helps in performing small-scale tasks effectually the house and gives you the choice for electrode attachments and globe systems.

It should be kept in listen that while 70 Amp welding machines are on the more durable and affordable end, they are extremely challenging to control and it volition require fourth dimension in both learning the machine and the process of welding with information technology.

How Many Amps Does A Lincoln 225 Welder Pull?

How many amps does a Lincoln 225 welder pull? As the name suggests, Lincoln 225 Welder pulls upwards to 225 amperes. Lincoln 225 Welder provides you lot with the range of 40 to 225 ampere pull without overloading the machine.

This welder is known to be one of the well-nigh powerful machines providing you with maximum versatility.

It'due south designed for operating on metals that are 16 gauge or heavier. The smoothen AC arc allows this machine to exist used on a multifariousness of metals.

The full range of 40 to 225 ampere selector switch enables you to quickly set the wielding current co-ordinate to your projection.

Any lesser than 40 amperes may not permit the machine to be used at its maxi mum capacities so always ensure that current pull is betwixt the mentioned ranges.

How Thick Tin can Yous Weld With A Hobart 140?

How thick can you lot weld with a Hobart 140? Since the Hobart 140 has generous operating parameters, it enables yous to weld from sparse gauge steel every bit little as 24 gauge up to a whopping ¼ inch steel plate.

While y'all can weld in the given range in a single pass, Hobart 140 allows yous to weld thicker materials with multiple passes too.

The Hobart 140 is i of the most versatile machines due to its compactness and constructive design.

Information technology is a wire feed MIG welder designed to run on the household standard of 115 V of power.

It'due south relatively easier to prepare and runs flux-cored steel, solid and aluminum wire.

Its range for thickness allows you to piece of work on motorcar bodies, household repairs, or even heavy-duty projects that would require extra power.

If you are interested in welding gear or tools, then but follow the link to our recommendation page where you lot tin see all welding accessories we dear and apply (NO CRAP)

Oftentimes Asked Questions

Here are a few common questions people oft have about MIG welder Amps:

Can I Put A 50 Amp Plug On A 30 Amp Breaker?

The breaker capacity defines the limit of current withdrawal. For whatsoever breaker it is recommended that no more that 80% of the actual billow chapters is used.

Can I put a 50 Amps plug on a 30 Amp billow? No. 30 ampere billow defines the limit at 30 amperes strictly so you should non be using more than than 24 to 25 amperes when using a 30 Amp breaker.

You should not exceed the capacity of the circuit through the usage of high ampere requiring machinery. This will not only cause the circuit to malfunction simply could too potentially damage your device.

Can You Plug a 15 Amp Plug Into a 20 Amp Receptacle?

The receptacle value is always supposed to be higher than the plug that is being connected to information technology. Most household appliances include a 15 amp plus that makes them eligible to be used in 15 or 20 amp receptacle.

Can you plug a xv Amp plug into a 20 Amp receptacle? Yes, you lot can exercise it. A 15 amp plus has two parallel blades and a basis pin that can easily be plugged into a xx amp receptacle.

The twenty amp receptacle provides you with a various range of choices when it comes the plug being used only it should ever exist noted that the ampere limit should not be exceeded.

A 20-amp receptacle accommodates larger influx on current and enables you to utilise more heavy-duty appliances. Larger ability tools including welding machines can be used with a 20 amp receptacle.

How Many Amps Does A Lincoln 140 Use?

How many amps does a Lincoln 140 apply? This machine proves itself to be robust and reliable through its 140 Amp tool that gets the job washed on normal household power of 120 volts.

Information technology comes in two variants called 140 HD and 140 C chapeau both share the same ampere usage but differ in componential qualities.

Despite them existence variants, both welders all you to withdraw up to 140 amperes with no problem.

The minimum ampere requirement is 30 amperes and allows you lot to weld up to 5/16 inch for mild steel without gas and MIG welding upwards to 3/16 inch in a single pass with gas.

Lincoln 140 is 1 of the tiptop tier welding machines available on the market place.

Decision

When information technology comes to welding, in that location aren't many simple answers. That'south because so much of what you lot need to know to find the right answer depends on variables similar the type of piece of work yous're doing and the type of materials you're welding.

If y'all know that y'all have enough welding work to do that you are because investing in a machine, you should know the specific answers to those questions that volition permit yous to determine how much auto is enough and how much is too much.

sources:

https://www.millerwelds.com/resources/weld-setting-calculators/stick-welding-reckoner

https://www.mig-welding.co.uk/tig-estimator.htm

Recommended Reading

Can You lot MIG Weld in the Rain or when information technology'due south wet?

What'due south the Deviation Betwixt TIG and MIG Welding? Which one is improve?

Can MIG Welders Weld Aluminum? | How to successfully weld Aluminum?

How To Find The Correct MIG Welder Settings For Whatever Projection >> Video

Here are some of my favorite tools & equipment´s

Thank you for reading this article. I promise it helps you observe the almost recent and accurate information for your welding project. Hither are some tools that I use daily and hope yous´ll also find helpful.

There are affiliate links, so if you do decide to use any of them, I´ll earn a small-scale committee. Just in all honesty, these are the exact tools that I use and recommend to everyone, even my own family. (NO CRAP)

To meet all my of most up-to-engagement recommendations, check out this resources that I fabricated for you!

Best Overall

Recommendations

+ Great Products & Services

+ Approved

+ Save Thousands of Dollars

rodrigueztary1941.blogspot.com

Source: https://weldingtroop.com/how-many-amps-do-i-really-need-for-a-mig-welder/

Belum ada Komentar untuk "How Many Amps Can 18 Gauge Wire Handle 48v?"

Posting Komentar